Corn Puff Pola Making Machine Plant: Complete Guide

Introduction

In the modern food processing industry, extruded snacks like corn puff or "pola" have gained massive popularity. These crunchy, flavorful snacks appeal to a wide demographic, making them a lucrative product for entrepreneurs and manufacturers. Setting up a Corn Puff Pola Making Machine Plant is a strategic investment that can yield high returns with the right machinery, setup, and knowledge.

This guide provides an in-depth overview of the Corn Puff Pola Making Machine Plant – from machinery, process flow, technical specifications, raw material requirements, plant layout, and more.

---

1. What is Corn Puff (Pola)?

Corn Puff or Pola is an extruded snack made primarily from cornmeal or other grains. It is produced by forcing moistened starch-rich materials through an extruder, where it is cooked and shaped under pressure and heat. When the material exits the die of the extruder, the sudden drop in pressure causes it to puff, resulting in a light, crunchy texture.

Types of Corn Puff Products:

Ring-shaped puffs

Ball-shaped puffs

Stick or cylindrical puffs

Cheese puffs

Masala or spiced corn pola

---

2. Market Potential

Corn puff snacks have a wide market base due to their taste, affordability, and ease of consumption. Both urban and rural markets contribute to rising demand. With changing lifestyles, the demand for ready-to-eat snacks is growing globally.

Why Invest in a Corn Puff Pola Plant?

Low production cost with high-profit margins

Easy availability of raw materials

High consumer demand

Export potential

Scalability from small-scale to fully automated industrial units

---

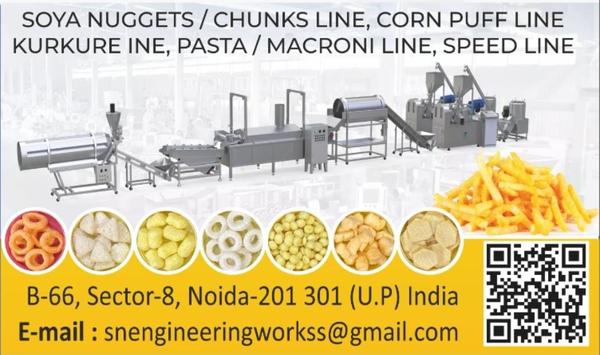

3. Components of Corn Puff Pola Making Plant

A typical plant comprises several machines that form a complete production line. Below are the essential machines and their roles:

A. Raw Material Mixer

Function: Mixes corn grits/flour with water and additives uniformly.

Types: Ribbon blender or paddle mixer

Capacity: 50 kg/hr to 500 kg/hr

B. Screw Conveyor

Function: Transports the mixed material to the extruder without spillage

Material: Food-grade stainless steel

C. Puff Extruder Machine

Function: Core machine that uses heat and pressure to extrude and puff the material

Power: 20 HP to 60 HP

Die options: Different shapes and sizes for varied product output

D. Cutter

Function: Cuts extruded material to desired length

Types: Rotary or adjustable blades

E. Flavoring Drum / Seasoning Machine

Function: Coats the puffed products with flavors, spices, or oil

Material: SS304 food-grade stainless steel

F. Conveyor Belt

Function: Transports products between machines and to packaging area

G. Roaster / Dryer (optional)

Function: Removes residual moisture to increase shelf life

H. Packaging Machine

Function: Packs the final product into pouches or containers

Types: Semi-automatic or automatic form-fill-seal (FFS) machines

Introduction

In the modern food processing industry, extruded snacks like corn puff or "pola" have gained massive popularity. These crunchy, flavorful snacks appeal to a wide demographic, making them a lucrative product for entrepreneurs and manufacturers. Setting up a Corn Puff Pola Making Machine Plant is a strategic investment that can yield high returns with the right machinery, setup, and knowledge.

This guide provides an in-depth overview of the Corn Puff Pola Making Machine Plant – from machinery, process flow, technical specifications, raw material requirements, plant layout, and more.

---

1. What is Corn Puff (Pola)?

Corn Puff or Pola is an extruded snack made primarily from cornmeal or other grains. It is produced by forcing moistened starch-rich materials through an extruder, where it is cooked and shaped under pressure and heat. When the material exits the die of the extruder, the sudden drop in pressure causes it to puff, resulting in a light, crunchy texture.

Types of Corn Puff Products:

Ring-shaped puffs

Ball-shaped puffs

Stick or cylindrical puffs

Cheese puffs

Masala or spiced corn pola

---

2. Market Potential

Corn puff snacks have a wide market base due to their taste, affordability, and ease of consumption. Both urban and rural markets contribute to rising demand. With changing lifestyles, the demand for ready-to-eat snacks is growing globally.

Why Invest in a Corn Puff Pola Plant?

Low production cost with high-profit margins

Easy availability of raw materials

High consumer demand

Export potential

Scalability from small-scale to fully automated industrial units

---

3. Components of Corn Puff Pola Making Plant

A typical plant comprises several machines that form a complete production line. Below are the essential machines and their roles:

A. Raw Material Mixer

Function: Mixes corn grits/flour with water and additives uniformly.

Types: Ribbon blender or paddle mixer

Capacity: 50 kg/hr to 500 kg/hr

B. Screw Conveyor

Function: Transports the mixed material to the extruder without spillage

Material: Food-grade stainless steel

C. Puff Extruder Machine

Function: Core machine that uses heat and pressure to extrude and puff the material

Power: 20 HP to 60 HP

Die options: Different shapes and sizes for varied product output

D. Cutter

Function: Cuts extruded material to desired length

Types: Rotary or adjustable blades

E. Flavoring Drum / Seasoning Machine

Function: Coats the puffed products with flavors, spices, or oil

Material: SS304 food-grade stainless steel

F. Conveyor Belt

Function: Transports products between machines and to packaging area

G. Roaster / Dryer (optional)

Function: Removes residual moisture to increase shelf life

H. Packaging Machine

Function: Packs the final product into pouches or containers

Types: Semi-automatic or automatic form-fill-seal (FFS) machines