A Kurkure machine is a highly efficient food processing unit designed to manufacture crunchy and tasty snacks like Kurkure, Cheetos, and other extruded products. It works on the principle of extrusion technology, where cornmeal and other ingredients are mixed, heated, and pushed through a specially designed extruder to give the unique twisted and crunchy shape. The machine is equipped with advanced features such as an automatic feeding system, twin-screw extruder, cutting system, and flavoring unit to ensure uniform shape, size, and taste.

Kurkure machines are widely used in the snack industry because they offer consistent quality, high productivity, and low labor requirements. The machine allows manufacturers to use a variety of raw materials like corn grits, rice flour, and gram flour to create different flavors and textures. After extrusion, the product is fried or baked and then coated with seasoning using a flavoring drum.

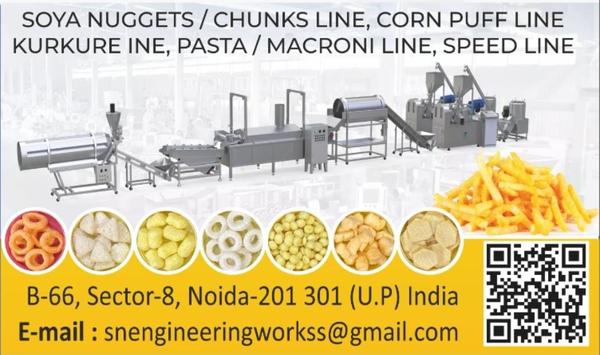

These machines are available in different capacities, making them suitable for both small-scale businesses and large-scale snack production plants. They are built with durable stainless steel to ensure hygiene and long-lasting performance. With easy operation, low maintenance, and energy efficiency, Kurkure machines have become an essential investment for companies aiming to meet the growing demand for ready-to-eat snacks.