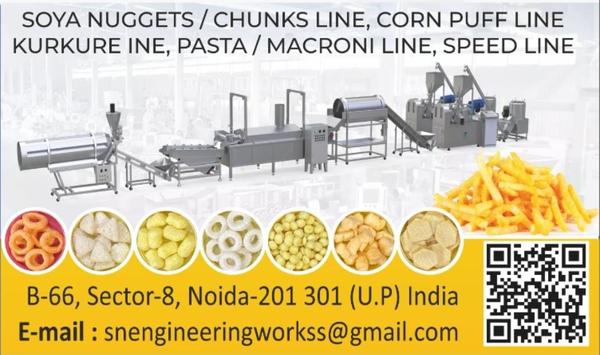

A Kurkure machine is a specialized food processing equipment designed to manufacture crunchy, puffed snacks like Kurkure and other extruded products. This machine works on the extrusion process, where cornmeal or similar ingredients are fed into the extruder, mixed, cooked under high pressure and temperature, and then shaped into the desired snack form. The machine is highly efficient and ensures uniform texture, crispiness, and taste.

The Kurkure making machine consists of several parts including a feeder, extruder, cutter, and fryer or roaster depending on the production line. The extruder is the key component that gives Kurkure its unique twisted and crunchy shape. Once extruded, the snacks are cut into small pieces and passed through frying or baking equipment, followed by seasoning with different flavors such as masala, cheese, or tomato.

Modern Kurkure machines are built with stainless steel for hygiene and durability, and they are designed for continuous production with low power consumption. They can produce large quantities of snacks in a short time, making them ideal for commercial snack manufacturers. With easy operation, low maintenance, and consistent quality output, the Kurkure machine is a profitable investment for food industries looking to enter or expand in the snack market.